High temperature test

High temperature test expose heat exchanger in high temperature and dry environment to check it’s limitation.

Components Inspection

HD image measurement to observe the components size, hole position, etc, with an accuracy of micron level.

Cyclic temperature test

Cyclic temperature test provide cyclic high temp. and low tem. on heat exchanger to check it’s limitation.

Constant hot and humid test

Constant hot and humid test to test heat exchanger’s hot resistance, cold resistance, dry resistance and humidity resistance.

Material Test

Use metallographic scope to analyze the internal structure and defects of alloy material in order to judge the quality.

Corrosion (salt spray) Test

Artificial simulated salt spray environment to assess the corrosion resistance of heat exchanger.

Performance Test

The ambient temperature can be set to test the heat transfer of the heat exchanger or system under specific conditions.

Seal Detection

Small vulnerabilities can be detected with high accuracy

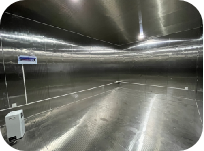

Reliability Test -- High Temperature

It can simulate high temperature conditions and test the heat transfer performance and reliability of batch products at specific ring temperatures.

Reliability Test -- Low Temperature

It can simulate low temperature conditions and test the heat transfer performance and reliability of batch products at a specific ring temperature

浙ICP备2021015418号

浙ICP备2021015418号